Whyte Laydie Banjo Repair

Several years ago Joe Rorex. a barber and friend of mine from around Chattanooga, brought this old banjo to me for repairs. If my memory is correct, I believe the serial number dated it to about 1908 or so. Joe was a banjo picker and bass player. He had purchased this banjo from someone and it was in pretty rough condition. It had apparently been in someone’s attic for a long time. I’ll try to document what was done to this banjo. Joe didn’t want to spend a fortune on it so we did what we could to put in in a presentable condition and make it somewhat playable. It is easy to as one guy said, “To put a thousand dollar saddle on a hundred dollar horse”. I will keep my comments brief since there are so many picture of this repair.

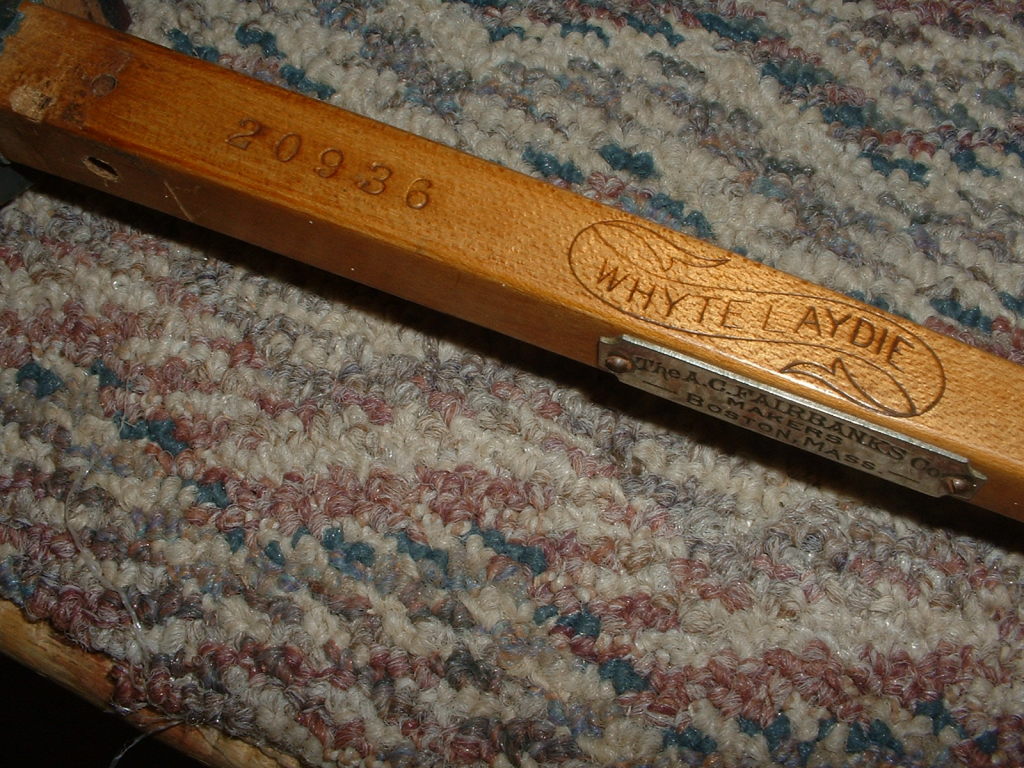

Here is the neck.

Someone had done a previous repair with JB Weld or some similar product. Believe me, this stuff was hard. It took a long time to remove it without damaging the wood.

The neck joint has failed.

Also the fingerboard was loose.

The peghead overlay was split and the neck halves were pulled apart.

What have I gotten myself into? I removed the fingerboard.

I removed the peghead overlay. (In pieces as you can see.)

After removing the dowel stick from the neck, (it took some coaxing) I separated the halves of the neck.

The narrow strip of wood in the center (ebony?) had deteriorated and weakened the joint.

I chose a strip of rosewood to go between these two halves of the neck.

After some CAREFUL cleaning and scraping and taping I was able to join these neck halves back together. I think I had to make a new heel cap. I really can’t remember at this point. I didn’t want to refinish any more of this neck than was absolutely necessary.

The neck went together well. (so far so good.)

Now I set about trying to rebuild this peghead overlay so I could get this gryphon inlay back in it.

The back side of overlay.

Here is the overlay installed on the neck. I remember that I dropped a little piece of this delicate pearl inlay in the floor below my work bench in the process. This was a little piece about the size of kernel of un-popped popcorn. I spent several hours looking for it in the dust and wood shavings. I finally swept the floor and got a piece of screen wire to filter the debris through. I found it after a while. This inlay is one of the things that distinguish these banjos. I probably could have made a replacement, but that would be another story.

All back together.

I refinished the overlay only.

Then I glued the stick back into the neck. Isn’t that pretty how the manufacturer made this look so professional? Rounded edges look good to me. The logo had a good look to it and the little metal plate finishes it off.

The inside of this shell had some tortoise like material that had deteriorated. I didn’t replace that since I didn’t have anything to match it. You know we were working on a limited budget. I had already done about 3 times as much work as I charged him for but it was also a learning process and a challenge for me.

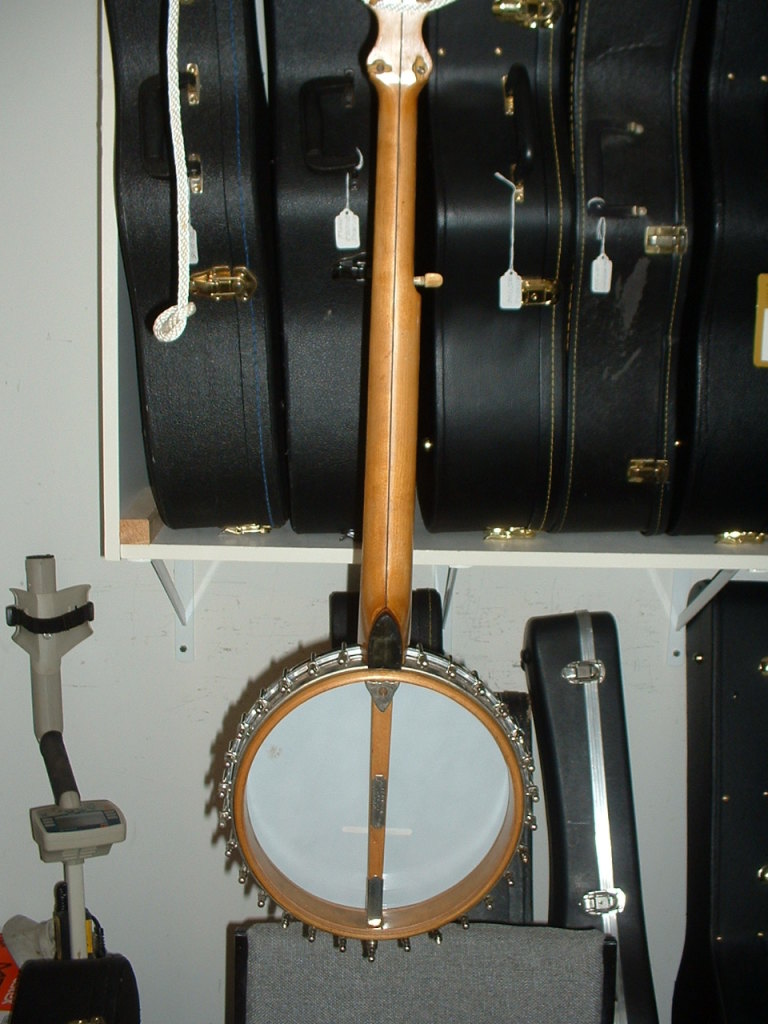

Here it is assembled.

Looks like a banjo again.

I had to install a Nichols Bridge on it.

The old case was deteriorated. I remember glueing some of the cloth back into place.

It looks a little better.

The action was high on it. We didn’t attempt to address that problem. The neck repair went as well as I could ask. By the way, notice the ivory 5th string peg. These old necks didn’t have a truss rod and relied on the hard maple to keep them straight. Joe Rorex has since passed away. I think he sold this banjo to someone before he died.

![]()

Be the first to comment on "Whyte Laydie Banjo Repair"